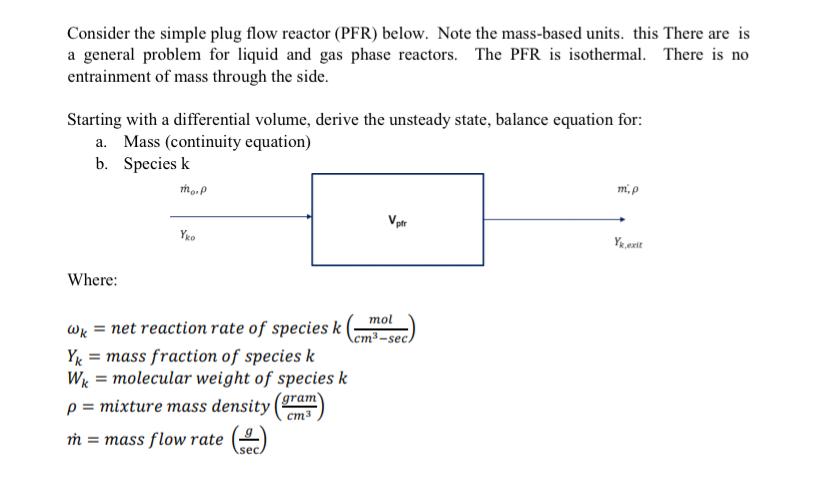

plug flow reactor equation

We are going to start with PFRs and then go to CSTRs a little later. The flow linear velocity u ms and the concentration of species i C i molm3 can be introduced as.

Plug flow reactor.

. Isothermal Plug Flow Reactor Model. A i r A - dF Ai dV. F Ai Q.

Remember the equation CA molm3 F A mols v m3s. Equations reactor sizing for constant volume and variable volume processes. Plug flow reactors PFR and continuous stirred tank reactors CSTR.

This document was uploaded by user and they confirmed that they have the permission to share it. In a plug flow reactor nutrients and sometimes organisms are introduced to the reactor continuously and move through the reactor as a plug. V FAO1 R XfRXf 1 RdXA rA where V is the volume of the reactor m 3 FAO is the mass flow rate of the feeding stream kgh R is the recycle ratio Xf is the conversion of products and rA is the kinetic expression of the chemical reaction 9.

Gas Limiting and Plug flow of liquid Constant gas phase concentration Height valid for pure gas at high flow rate Relative distance from catalyst particle QA QA ka A Al Arksap Al As Ar 0 l lz l lz dz l B Net input by convection Input by Gas-Liquid Transport Loss by Liquid-solid Transport - 0 1 2 3 4. Plug Flow Reactors PFRs General Mole Balance Equation IN - OUT GENERATION ACCUMULATION At steady state- Differentiating that gives- For single reactions in terms of conversion- The differential form of the PFR mole balance is- The integral form is- Algorithm for Isothermal Reactor Design Chapter 4 EXAMPLE. To achieve this form for plug-flow reactors we begin by applying the balance to a small differential volume in which there are no spatial variations Figure R137-1.

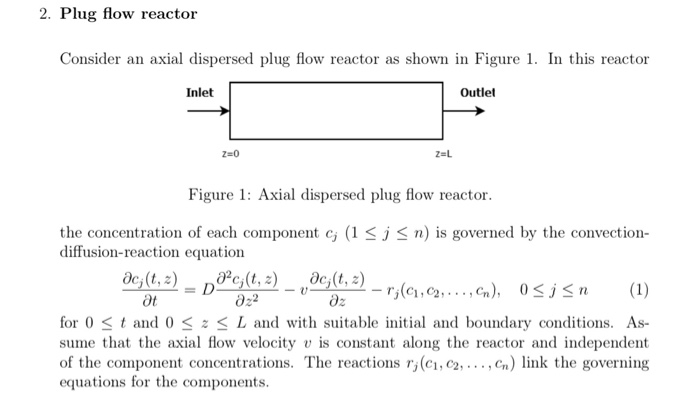

This is a differential equation that can be readily. 593 Nonideal Plug-Flow Reactor via Transfer Matrix In a nonideal PFR besides transport by convection some diffusion occurs in the axial direction. For each of the reactors considered above the appropriate design equation is 827.

Twenty percent of the recycle sludge flow COD was observed. On the right hand side the first term is the convection term the second term is the. Where is the Darcy friction factor from the above equation or the Moody Chart is the sublayer thickness is the pipe diameter is the density is the friction.

The plug flow reactor model is a model used to describe chemical reactions in continuous flowing systems of cylindrical geometry. The design of Chemical Reactors is based on a few. WHG Lecture 6 correction.

For such a reactor a model equation of the form 5171 ɛ ɛ b c t D eff 2 c x 2 v c x k a c is obtained. The number of moles of species i in is Figure CD137 PFR with heat gain or. Basic reactor models plug flow reactor The Convection-Diffusion Equation.

Chemical Reaction Engineering CRE deals with the design of Chemical Reactors to produce chemicals. Combining reactors with separations. Plug flow will be achieved if the sublayer thickness is much less than the pipe diameter.

Derivation of the design equation for a plug flow reactor with first order kineticsPresented by Professor Alan Hall University of Huddersfield. How choice of reactor affects selectivity vs. X concentration of microorganisms at any point in contact reactor Xo influent concentration of microorganisms 106 E.

The PFR model is used to predict the behavior of chemical reactors of such design so that key reactor variables such as the dimensions of the reactor can be estimated. Plug Flow Reactor Operating a mass balance on the selected volume V A l and assuming steady-state conditions we obtain ttt0 V dm Qc Qc rdV dt 17 hence cout V cin Q cout Q. The system may be either contained as in a water main oil pipeline or blood vessel or open as in a shower curtain stream or canyon seep.

Coli100 ml k d 5 hr-1 r c rate of chlorine decay from microorganism Cl-demand -k c X k c 10-5 mg-chlorineL100mL-1hr-1 2 rate expressions 2 constituents 2 coupled mass balances find. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators. Download Calculation Of Plug Flow Reactor Design.

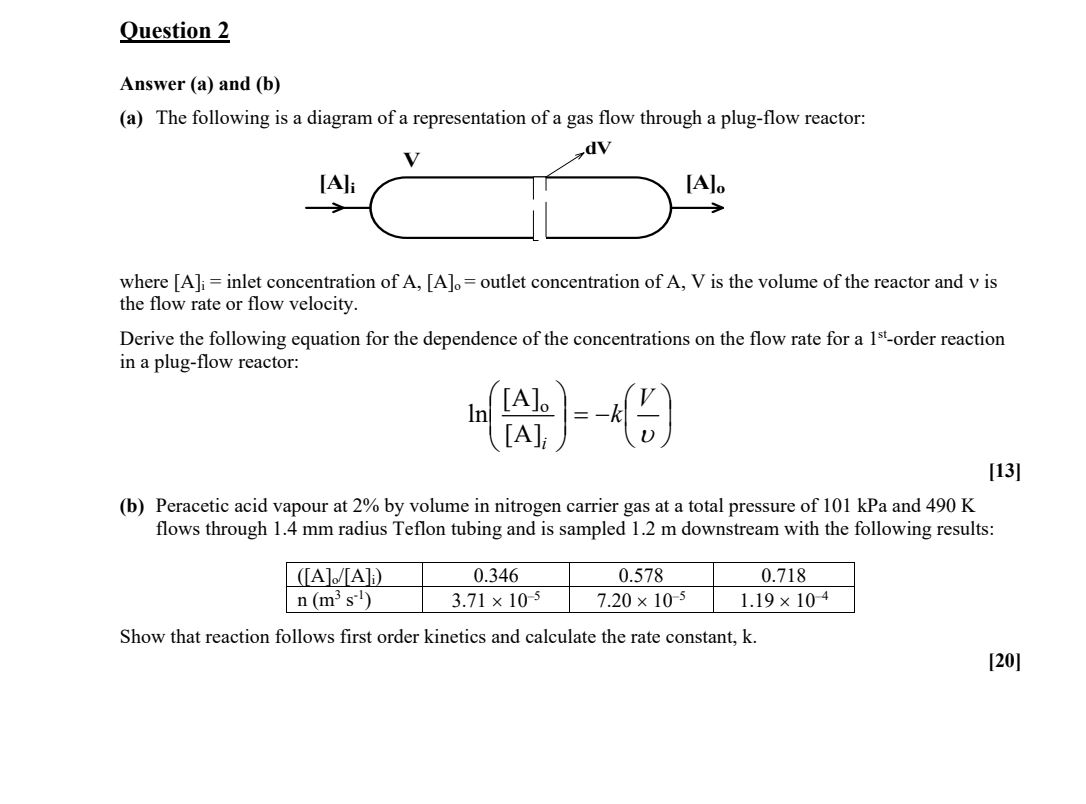

62 which is the basic form of the design equation for a plug-flow reactor V is the reactor volume G is the total mass flow through the reactor Cao is the concentration of A at inlet in moles per unit mass of feed Xa is the fractional conversion of A. Chemical Reactor is known as the heart of any chemical plant since the new chemicals are produced only in this vessel and the economics of the entire plant depends on the design of reactor. On application of the above to Equation 1 the mass balance on i becomes.

Reactors in series and in parallel. When like terms are cancelled and the limit dx 0 is applied to Equation 2 the mass balance on species i. In an ideal plug flow reactor it is assumed that.

KDW 8 The plug flow reactor. No volumetric flow variation In case the volumetric flow within the reactor stays constant Q i Q o Q at any point in the reactor the reaction speeds above can be simplified and expressed as a function of the concentration. The equations governing the behavior of the plug flow reactor are simplified versions of the general relations for conservation of mass energy and momentum4 They can be derived most easily by writing balances over a differential slice in the flow direction x.

WHG 9 Reactor size comparisons for PFR and CSTR. Consider j plug flow reactors connected in series and leti23 -fh represent the fraction conversion of the limiting reagent leaving reactors 1 2 3. By applying a constant flux of CT USA followed by a plug-flow contact reactor a stain- ozone to a mixed liquor and changing the fluid-dynamics less steel pipe of 10 metres 20 cm in diameter 03 m3 conditions an increase of 94 in the solubilization of in volume.

For steady-state operation of a plug flow reactor the basic design equation equation 829 can be written as. Fluid going through a PFR may be modeled as flowing through the. If you are author or own the copyright of this book please report to us by using this DMCA report form.

There are two main types of continuous flow reactors.

Plug Flow Reactor Pfr Sizing And Conversion Example Youtube

Plug Flow Reactor Vapourtec Ltd

Matlab In Chemical Engineering At Cmu

Design Equation Of Plug Flow Reactor Chemical Reaction Engineering Lecture 08 Hindi And Urdu Youtube

Sizing A Plug Flow Reactor Pfr Youtube

Plug Flow Reactor Model A Plug Flow Reactor Pfr Model Is Used By Justin Mitchell Medium

Solved Consider The Simple Plug Flow Reactor Pfr Below Chegg Com

Solved 4 20 Points Consider A Plug Flow Reactor As Chegg Com

Plug Flow Reactor Design Equation Youtube

Plug Flow Reactor With First Order Kinetics Performance Equation Youtube

Introduction To Energy Balances For Plug Flow Reactors Youtube

Isothermal Plug Flow Reactor Part 1 Youtube

2 Plug Flow Reactor Ler An Axial Dispersed Plug Flow Chegg Com

Mole Balance On A Plug Flow Reactor Youtube

Computational Scheme For A Plug Flow Reactor Defining The Function Download Scientific Diagram

Solved Question 2 Answer A And B A The Following Is A Chegg Com

Consider The Following System Differential Equation Chegg Com

Conversion And Reactor Sizing Lec 4 Week 4 Definition Of Conversion For The Following Reaction The Reaction Can Be Arranged As Follows How Far The Above Ppt Download